Panda Piping Ltd. is dedicated to delivering cost effective pre-fabricated piping systems to a vast consumer base on time with supreme quality.

Panda Piping Ltd. is dedicated to delivering cost effective pre-fabricated piping systems to a vast consumer base on time with supreme quality.  Provide highest quality product through our highly skilled, experienced and dedicated employees, state-of-the-art equipment and manufacturing process.

Provide highest quality product through our highly skilled, experienced and dedicated employees, state-of-the-art equipment and manufacturing process. - Over 15 Registered procedures

- GTAW, SMAW, GMAW, and FCAW

- Sch 5 to Sch160 Pipe Wall Thickness

- From ½” Pipe Diameter up to 36”

- All Welders Certified and Registered

- Full Material & Consumables Traceabilityw

![]()

Panda Piping Ltd. is certified in accordance with CSA Standard B51, Boiler, Pressure Vessel and Pressure Piping Codes:

- ASME B31.1 Power Piping

- ASME B31.3 Process Piping

Our current 17,000 sq. ft. facility offers full service manufacturing, cutting-edge pipe welding techniques, full skid piping assembly with electrical services, and precise machining.

MECHANICAL, ELECTRICAL, OR PREFABRICATED FRAMES AND SPOOLS, WE DO IT ALL !!!

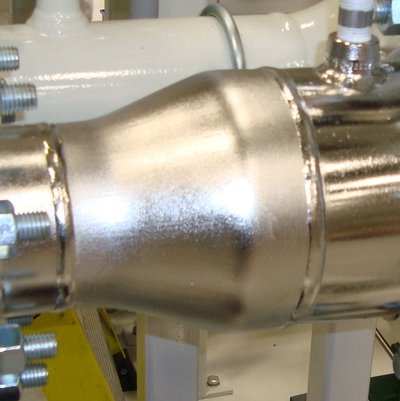

Our expertise lies in GTAW, SMAW, GMAW, FCAW pipe welding techniques for light to heavy wall pipe welding, ranging from Sch10 to Sch160, and pipe diameters up to 36”.

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) welding or metal active gas (MAG) welding, is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to melt, and join.

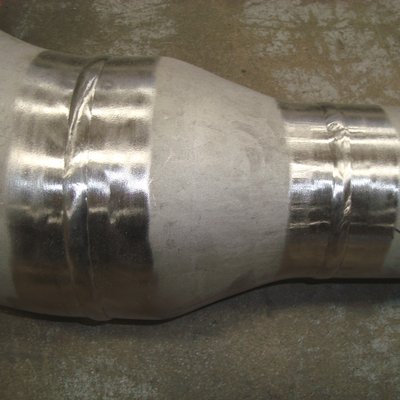

SURFACE FINISH & PASSIVATION

Passivation is the process of treating or coating a metal in order to reduce the chemical reactivity of its surface. In stainless steel,passivation means removing the free iron from the surface of the metal using an acid solution to prevent rust and improve corrosion resistance.

Blasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, or remove surface contaminants. Bead blasting is the process of removing surface deposits by applying fine glass beads at a high pressure without damaging the surface.

Electropolishing is the electrochemical treatment of metals to obtain a smooth, corrosion-resistant finish and improve metal durability and performance. Electropolishing is an extremely effective process because unlike conventional metal finishing, electropolishing does not smear, bend, stress or fracture the metal.

Mechanical polishing is the smoothing of a surface using mechanical tools and abrasives. Mechanical polishing is performed in steps with progressively finer abrasives until a desired smoothness is achieved.